Li Chenhao Visits National Worker Pioneer Team before Labor Day

Recently, the All-China Federation of Trade Unions (ACFTU) held a conference to honor the recipients of the 2024 National May 1 Labor Award and the National Worker Pioneer accolade. Among the awardees of the honorary title of the 2024 National Worker Pioneer was the kilometer-level superconducting cable operation and maintenance team of Shanghai International Superconductor Technology Co., Ltd. based in Baoshan. Prior to Labor Day on May 1, Li Chenhao, Secretary of the CPC Baoshan District Committee, led a team to visit the team and extend festive greetings to the diligent workers.

During his visit, Li Chenhao attentively listened to the team’s information, toured the company’s exhibition hall and production workshop, learned in detail about the production conditions of the superconductor production line, and familiarized himself with the company’s efforts in the R&D and application of superconducting technology, superconducting magnets., precision manufacturing, and medical devices. Li pointed out that the company’s intensified efforts in the R&D and application innovation of superconducting materials, with a focus on new materials, processes, products, and markets, created a new ecosystem for industrial development and unlocked new efficiencies in technological R&D. He expressed his expectation for the team to translate the honor into a sense of responsibility and motivation, encouraging them to continue playing an exemplary and leading role, forging ahead with enterprise and resolve, and strengthening technological innovation and empowerment. Li further urged them to maintain their focus on the main business of high-tech manufacturing and to lead industrial transformation and upgrading through technological innovation, thereby contributing to Baoshan’s “northern transformation”.

2024 National Worker Pioneer

Shanghai International Superconductor Technology Co., Ltd.

Kilometer-level superconducting cable operation and maintenance team

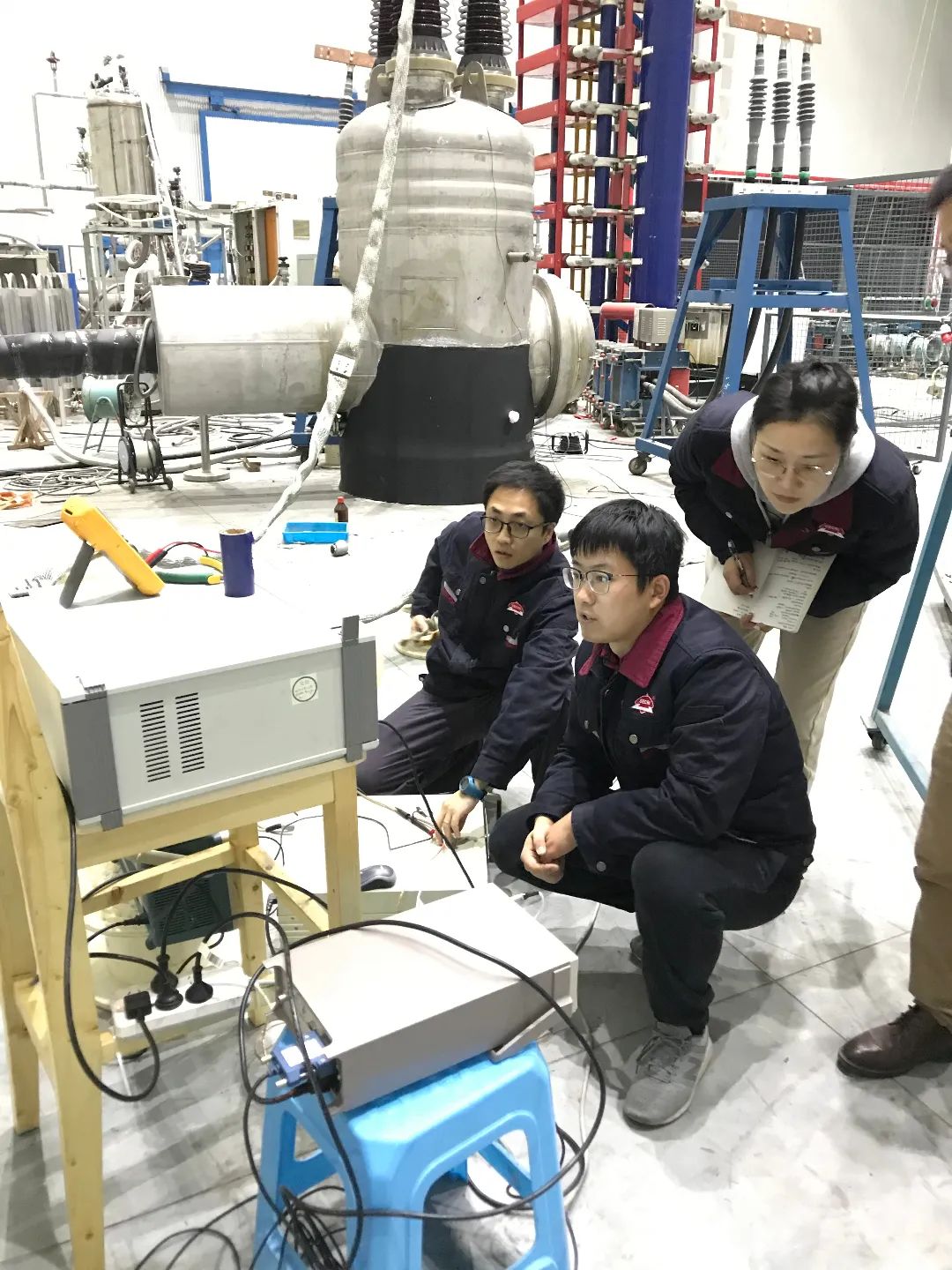

The kilometer-level superconducting cable operation and maintenance team of Shanghai International Superconductor Technology Co., Ltd. is currently the only team in China that has fully mastered the design and manufacturing technology of the superconducting cable system with independent intellectual property rights. Through 20 years of relentless dedication, the team has achieved groundbreaking milestones by transferring the technology from the laboratory to the production line and putting into operation the world’s first kilometer-level superconducting cable demonstration project. The team’s innovations, spanning from key materials and cable structure to pipe jacking installation as well as operation and maintenance, have provided the State Grid with a comprehensive suite of solution for the engineering application of superconducting cables.

Initiating the research of high-temperature superconducting (HTS) cables in 2003, the team completed the development of China’s first set of superconducting cable production equipment in 2007, accomplished the production of China’s first superconducting cable system and manufacturing equipment in 2010, and subsequently completed a 50-m-long, 35-kV HTS cable system demonstration project in 2013, which boasted the highest operating load in the world. In 2019, the team undertook the construction of China’s 1-km superconducting cable demonstration project, a strategic emerging industry initiative in Shanghai. This was the first time in the world that a superconducting cable was installed in the central urban area of a megacity. Covering 49,000 end users in Shanghai’s Xuhui District, the project has an annual power transmission capacity of 180 million kWh. In December 2021, the world’s first fully commercial 35-kV kilometer-level superconducting power transmission project was put into operation, creating five groundbreaking achievements: the first superconducting cable project supplying power to urban load centers, the largest transmission capacity in a commercial superconducting cable project, the longest transmission distance in a superconducting cable project, the only superconducting cable project using duct laying across the entire cable route, and the only superconducting cable project with double joints.

Over the past two decades, the team has been committed to improving the key components of superconducting cables, prolonging the life of vacuum insulated pipes, overcoming technical challenges, conducting rigorous tests in harsh environments, and mitigating various influencing factors such as lightning shocks, thermal cycling, joint wear, and refrigeration system failures. These endeavors have elevated the product quality from the laboratory level to the engineering application level, enhancing the vacuum maintenance-free life from 5 years to 10 years, reducing the leakage and outgassing rate (factory) from 10-5Pa*m ³/s to 10-7Pa*m ³/s, and improving the vacuum degree (factory) from 1-5 Pa to ≤ 0.5 Pa. With all core technologies developed domestically, the team has promulgated 1 International Electrotechnical Commission (IEC) standard, 1 national standard, 1 machinery industry standard, and 2 social organization standards in the field of superconducting cables, filling the gaps in international standards. Additionally, the team is in the process of compiling 1 energy standard and 3 enterprise standards.

As a research team engaged in cross-disciplinary collaboration, the team has continuously enhanced the manufacturing technology of superconducting cables while leveraging modern information technology to support their industrial application. Overcoming the challenge of lacking global precedents, the team has independently developed operation control systems, optimized control strategies, and established an operation and maintenance model integrating unattended functioning, remote real-time monitoring, and regular inspections. Utilizing cloud processing of digital parameters, the system enables data sharing and real-time monitoring and reduces reliance on manpower, allowing team members to comprehensively understand system dynamics and ensure the optimal operation of superconducting cables within the liquid nitrogen temperature range of minus 196 °C simply through terminal devices like mobile phones and tablets. This system has enabled the accurate collection of vast data on the electrical, mechanical, and superconducting properties of the cables. This has facilitated many pioneering achievements and led to the development of a series of standards for the production, testing, design, and construction of superconducting cables, laying a solid foundation for their widespread adoption.

Since the deployment of the superconducting cable system, it has supplied stable power to the grid for over two years, resilient against extreme weather conditions thanks to the intelligent control capabilities of the system. Notably, it has set a global record with a full-load operation of 2160.12 A for commercial superconducting power transmission lines. Comprehensive monitoring and detailed analysis by grid users have verified that the superconducting system operates normally and at an international leading level.

宝山汇APP

上海宝山微信

上海宝山微博